orion

Machine vision software developed by Synetra LLC, provides an intuitive interface for configuring and managing scanners and cameras.

This universal solution supports the entire range of Iris and LineScan cameras and scanners, making it suitable for a wide variety of tasks — including defect detection, rejection, sorting, and classification.

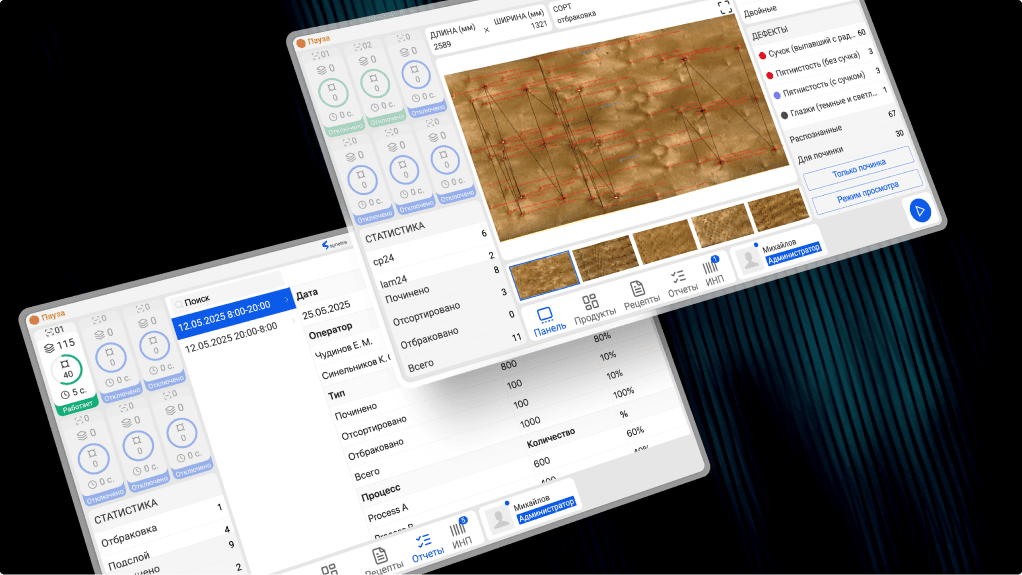

Screenshots of the orion software

Key Features

User-Friendly Interface

Easy to learn and operate, enabling operators to get started quickly without extensive training.

Multifunctionality

Supports various models of scanners, cameras, and optical sensors.

Flexible Configuration

Easily adaptable to the specific needs and requirements of your production processes.

Real-Time Feedback

Monitor the status of cameras, scanners, and output products in real time.

System Integration

Seamless integration with existing manufacturing systems to improve overall efficiency.

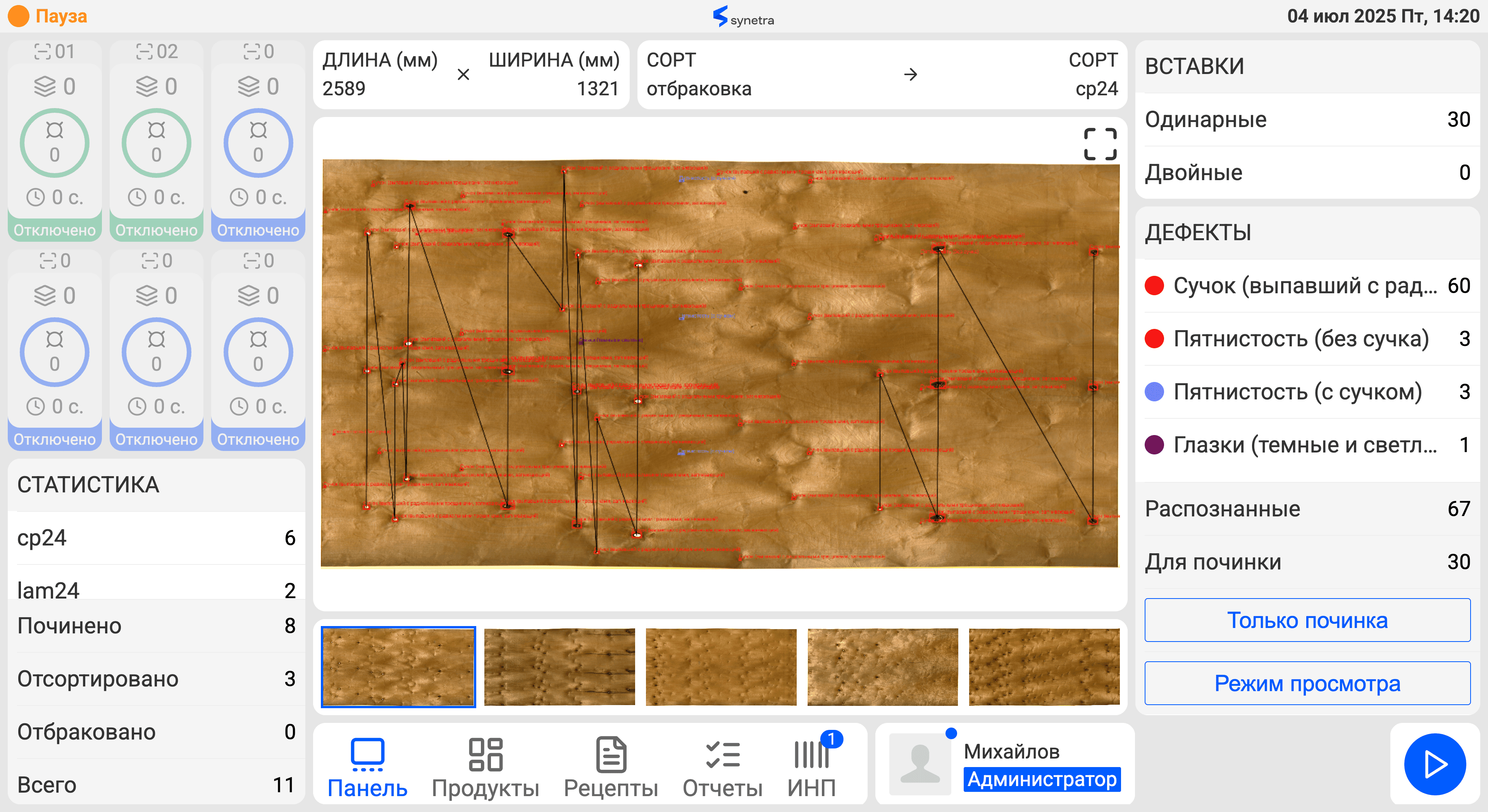

Screenshots of the software interface with real-world examples from manufacturing environments

Pricing

The final cost of the software depends on the base software modules, customization efforts, additional feature development, implementation services.

Each project is evaluated individually to provide a tailored solution and pricing.

Functional Capabilities

The orion software enables the following tasks

Quality Control on Production Lines and RTC (Robotic Technology Complex)

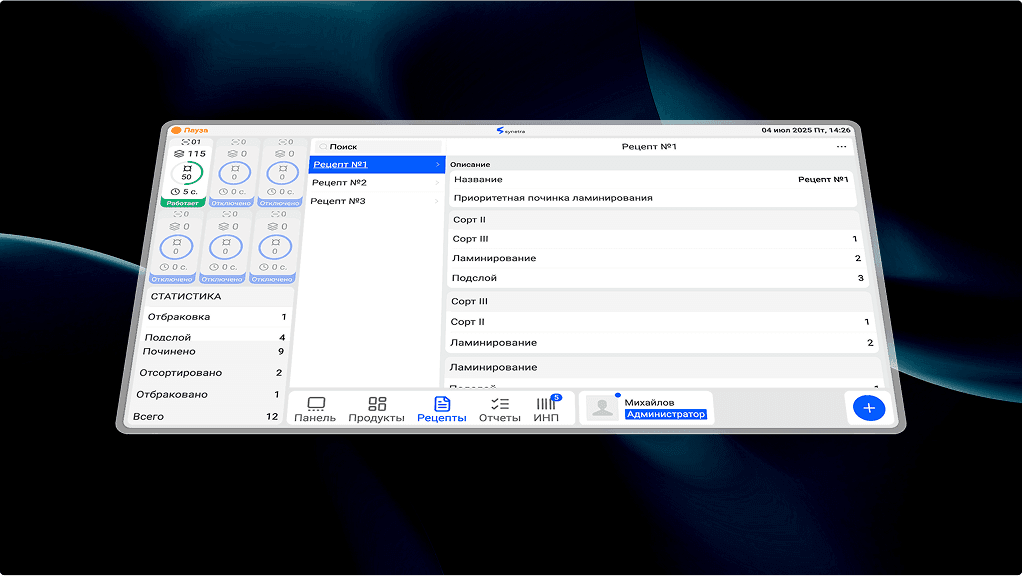

Create and edit recipes, including defect detection settings and product classification parameters

External device integration, work with logical conditions, cycles, variables, and subprograms

Calculate optimal repair paths for robotic systems

Line Monitoring

Display products moving through the production line and identified defects

Show current parameters from production line sensors and RTC cells

Log events and errors in real time

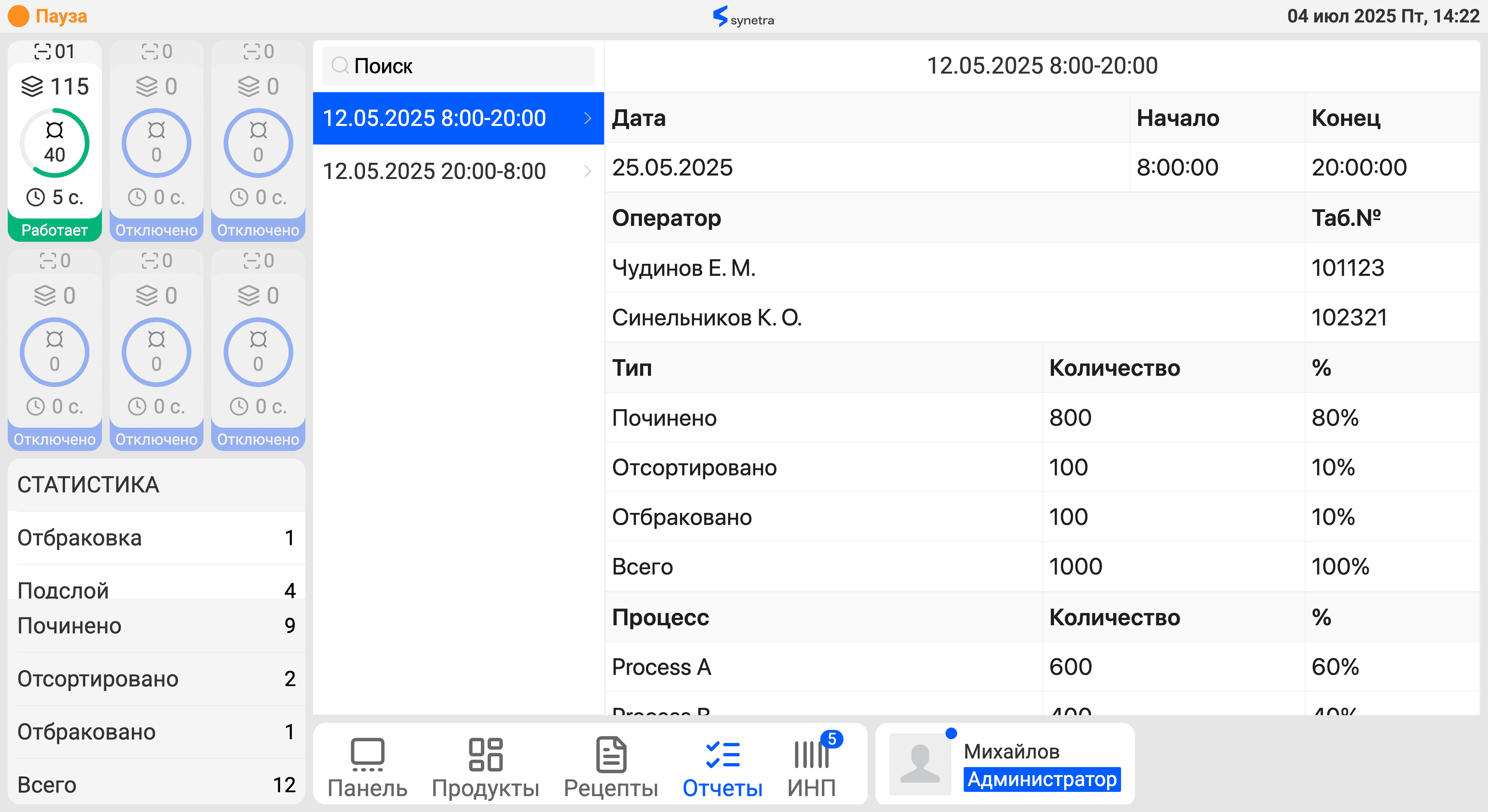

Generate reports on events, defect classification, RTC, and line status

External System Communication

Connect via MODBUS TCP, WebSocket, GRPC industrial protocols

Integrate with enterprise ERP systems

Interface with external equipment using discrete I/O modules in the robot control cabinet

Exchange data with external PLCs, conveyor systems, and RTC

User Interface and Experience

Intuitive graphical interface on programmable devices with touchscreen

Create and edit camera and scanner programs directly on the operator's device

Interactive defect alerts and reporting tools

Data Storage and Analysis

Integrated PostgreSQL database for storing statistics, reports, and user data

Import/export of recipes and scan logs in Excel or archive formats

Analyze historical logs to optimize RTC and production performance

Security and Access Control

Role-based access control (Operator, Expert, Administrator)

User authentication and action logging

Protection against unauthorized changes, including program modification tracking

Screenshot of the orion software

Software Installation

The software is delivered pre-installed with the hardware. No additional installation is required on the customer side.

Hardware Requirements

CPU

8 cores or more

RAM

32 GB or more

Disk Space

At least 2 GB

Operating System

Ubuntu 24.04

Network Connection

Ethernet (for device comms)

Display Resolution

1024x768 or higher

Video Memory

24 GB or more

User Manual

The user guide provides comprehensive information about the software’s features and safe operation of the associated scanning and camera systems.

Advantages

We offer not only cutting-edge solutions in neural networks and machine vision but also tools that help you stay competitive and ensure steady business growth.

Support & Training

At Synetra LLC, we understand the challenges of adopting new technologies. That's why we provide full technical support and training for your staff. Our expert team is ready to assist you every step of the way.